This year’s SAP Inspire on 17.11.2022 dealt with the topics warehouse and transport management and so of course with SAP EWM and SAP TM. I would like to share my impressions and experiences with you here.

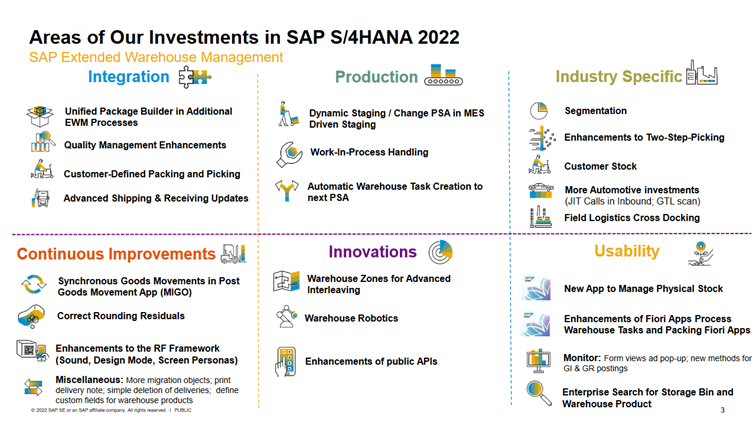

It started at 8 a.m. with a meet-up of SAP experts and SAP partners. I dialed in the room of the SAP warehouse management experts. Here the presentation with the already implemented innovations from 2022 was shown.

More detailed explanations on the individual points on the part of SAP can be found in the blog post under the link https://blogs.sap.com/2022/10/30/sap-extended-warehouse-management-in-sap-s-4hana-2022-whats-new/. Likewise, you can see the complete presentation again here.

There were no questions from the audience this early, so the SAP experts picked out the item SAP Warehouse Robotics, which was released in May 2022, and gave some more explanations.

This is about providing standard interfaces to robots and automated guided vehicles. EWM (both EWM 9.5 and EWM on S/4 on-premise) controls the robots or AGVs running the corresponding Integrated Services for Warehouse Robotics apps via the Warehouse Robotics interface on the SAP BTP.

In the expansion phase, the number of manufacturers served by the interface is expected to increase.

However, there are no plans to expand Warehouse Robotics so that it can also control AS/RS or conveyor lines. Here, SAP is thinking in terms of level rather than height.

8.45 a.m. we continued with the welcome and Keynote.

It is quite clear that SAP also sees the future for SAP EWM and SAP TM in the cloud. The familiar buzzwords “faster, more flexible and more sustainable” have been mentioned more often in this context.

SAP will continue to invest massively in logistics solutions in the coming years, as there is enormous demand on the market. One of the focal points will be the integration of logistics into other business areas. SAP TM, Planning and Manufacturing were directly addressed here.

Not to forget the area of sustainability. The aim here is to achieve more sustainable logistics by increasing efficiency with the help of software solutions.

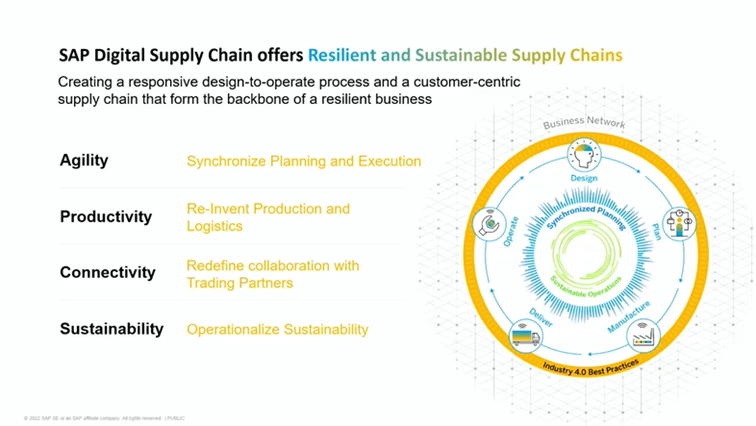

Dominik Metzger (Co-Head of Digital Supply Chain Development, SAP) presented the SAP Supply Chain Strategy.

As supply chains become more complex, the interdependencies and interconnections of the participants in these supply chains increase more and more.

These 4 points are the tools SAP wants to provide to customers to respond to supply chain disruptions.

- Agility

Disruptions that have an impact on the company’s own processes should be identified at an early stage, and it must be possible to derive appropriate courses of action from them.

- Productivity

Ever faster and higher output volumes have to be managed.

- Connectivity

There should be an eco-system of suppliers, transport service providers, shippers, OEM of machines and equipment.

- Sustainability

Operationally manage solutions to increase sustainability.

The top 3 strategic issues for 2023 were summarized as follows:

- Private Cloud – Advanced Logistics

(Robotics, Planning)

- Public Cloud – Standalone Edition

(low to medium complex operations)

- E2E – Logistics

(ASR, DMC, BN4L, Order Management)

As a second point, Jörg Michaelis (Head of Product Management Logistics Applications, SAP) presented the “Solution Portfolio Digital Logistics”.

The most important starting point for approaching problems is the high level of networking within the supply chain. For this, it is important to have highly efficient synchronized processes within the Warehouse Management, Transport Management, Yard Logistics and Production systems.

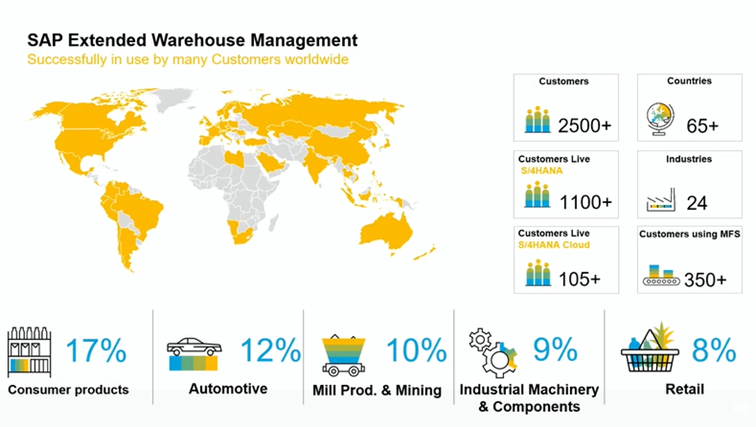

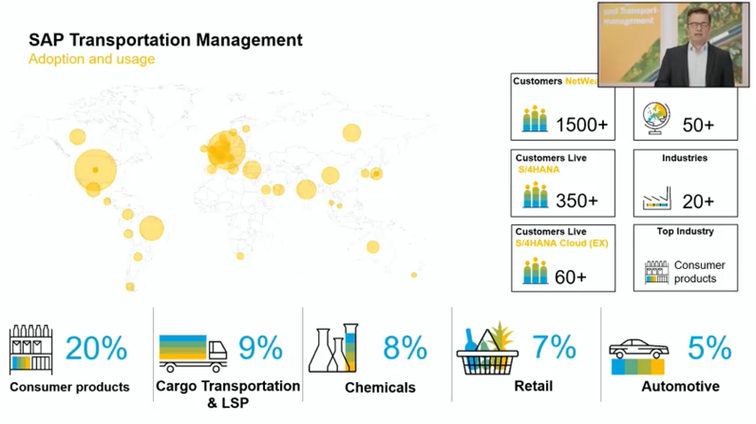

For SAP, the main component for this is EWM. Here are a few figures on SAP EWM and SAP TM.

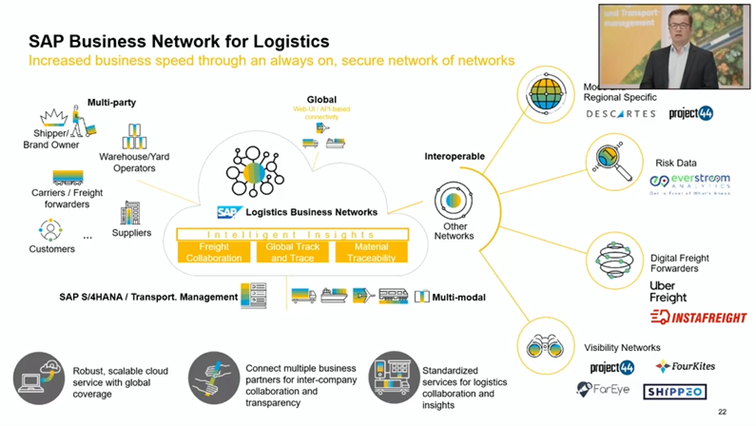

Via the SAP Business Network for Logistics, SAP builds the integration of the network participants once and then connects its customers. This enormously reduces the implementation effort in the rollout projects. This Business Network for Logistics is to be massively expanded in the coming years.

In the following, some product updates from 2022 were presented again. These include the above mentioned SAP Warehouse Robotics as an add-on to SAP EWM 9.5 or SAP EWM on S/4.

Innovations in the area of EWM-DMC integration are e.g. Dynamic Staging or Work-in-progress (WIP).

Dynamic Staging enables rescheduling of staging processes in case of supply chain or production line failure by rescheduling the staging to another production supply area (PSA), confirming the staging to the new PSA and sending the inventory change notification.

During work-in-progress, a generic product with inventory is created in EWM for intermediate products. The product and inventory are not visible in ERP.

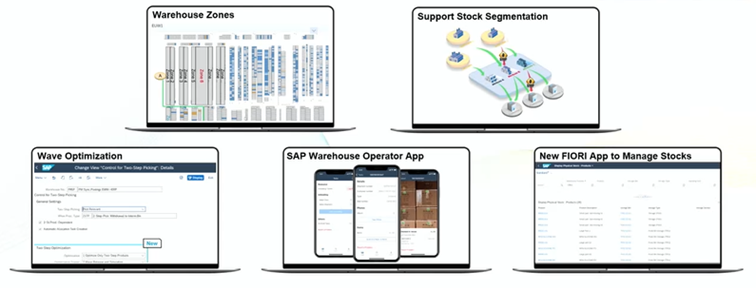

Further innovations in SAP EWM briefly summarized:

- Warehouse Zones

Storage bin attribution

To optimize efficiency and increase sustainability, the stacker receives the closest storage order, not the following queue order.

- Wave Management Optimization

Waves can now be simulated. Picking steps have been parallelized and are no longer based on static master data attributes. Instead of 20 individual picks, one pick is combined with 20 pieces.

- Stock Segmentation

Comes originally from the fashion industry. In the case of multiple sales channels (store, outlet or web store), the delivery channel accesses the correct inventory.

- Fiori

New app for inventory overview and management

- Warehouse Operator App

Here, the new Warehouse Operator App was launched in strategic cooperation with Apple. Here, the simplest processes are currently summarized in an app. This is constantly being expanded. However, the goal is not to replace the desktop app.

News in SAP TM

- TM Planning Improvements

Layer planning has been extended, different products with the same dimension can now be packed on one layer.

The loading plan now offers a layer-oriented view. The map allows drag & drop of a freight order onto another freight order.

- Incoterm Handling

The Incoterms are now digitized across all documents. This has an influence on the section creation in SAP TM. The Incoterm location is now managed as TM location.

- Charge calculation for planned distance and duration

- Analytics: Dashboard for disputes

- ASR: Delivery handling for customer returns

- new layouts for the Transport Cockpit in Basic TM

- Integration in SAP Direct Distribution

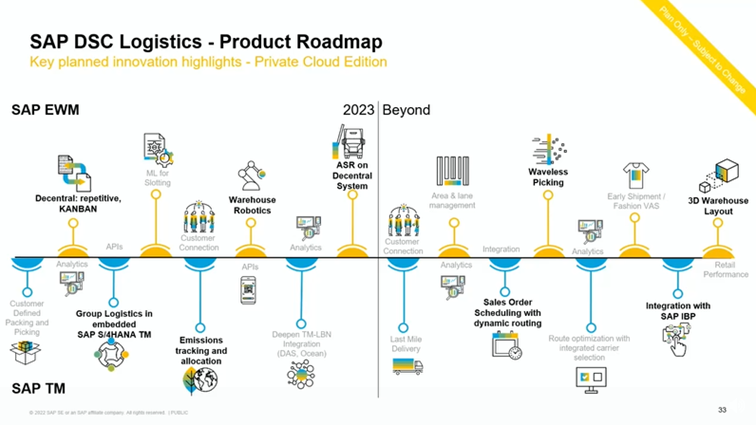

Finally, the roadmap for 2023 was presented.

As already mentioned, SAP EWM and SAP TM will move to the cloud in the future. Both modules are to be hosted stand-alone in the public cloud and can be connected to an ECC or S/4. This increases flexibility for customers.

However, SAP is also aware that this solution is not suitable for all warehouse types. This deployment option is not suitable for complex automated high-bay warehouses.

Enclosed is a graphic of the SAP DSC Logistics – Product Roadmap.

The most important insights from the key note are:

- Strong investment in product competence

- Focus on End-to-End Logistic integration

- Intelligence for sustainability and resilience

This was the end of the key note and it went into the presentation of the customer projects with the SAP partners.

There were also 10 partner presentations, but they ran in parallel. Here I hope that the corresponding recordings will be provided later.